Build Defect Detection AI for Large-Area Bright Field Microscopy

In this article, we will learn how to create an AI model using Deep Block to detect defects in a large-area bright field optical micrograph.

Announcement

With support from the Korea National Nanofabrication Center(NNFC), we obtained large-area optical micrograph of an IC. In this article, rather than building a perfect AI to detect all types of defects in the bright field micrograph, we aim to quickly train an AI model to identify visible defects with minimal annotation and effort, completing prototyping in just a few minutes.

At present, Deep Block is accessible upon demo request and product purchase.

Because of persistent hacking attempts and breaches of license agreements by scam GEOAI startups in South Korea, we have paused our free online platform and are diligently seeking methods to safeguard Deep Block.

If you are interested in evaluating this model and accessing a free trial, please reach out to us by completing the form.

Model Training

To start, we created a new image segmentation project and open it in Console page.

In our project, we uploaded a single optical micrograph and aimed to develop a defect detector with minimal annotation.

The method entails scanning the entire large area image file using our rapidly prototyped model, enabling us to use the inference results as training data for future model development and optimization with minimal effort.

The detailed strategy is outlined here: https://www.deepblock.net/blog/training-with-few-annotations

We don't need to label all defects in this large image file.

Simply find visible defects and label them as small polygons.

The entire image exceeds 9000x17000 pixels, making it challenging for a person to manually draw all the defects present.

Let's annotate about 52 of them and proceed to train the model.

Set the epochs to 40, and let's divide the large-area micrograph into 17 by 33 sections for model training.

While using blob detection algorithms is generally more effective for identifying small defects than deep learning techniques, our model will still work well.

Although further dividing the image (e.g., using a 34 x 66 factor) could enhance performance, for this article, we'll proceed by clicking the DIVIDE & TRAIN button.

If you're curious about blob detection technology, refer to this article: https://www.deepblock.net/blog/blob-detection.

For more information on Deep Block's image division technology, read the following article: https://www.deepblock.net/product/manual/how-to-divide-large-images-for-inference.

After a few minutes, the training process will be completed.

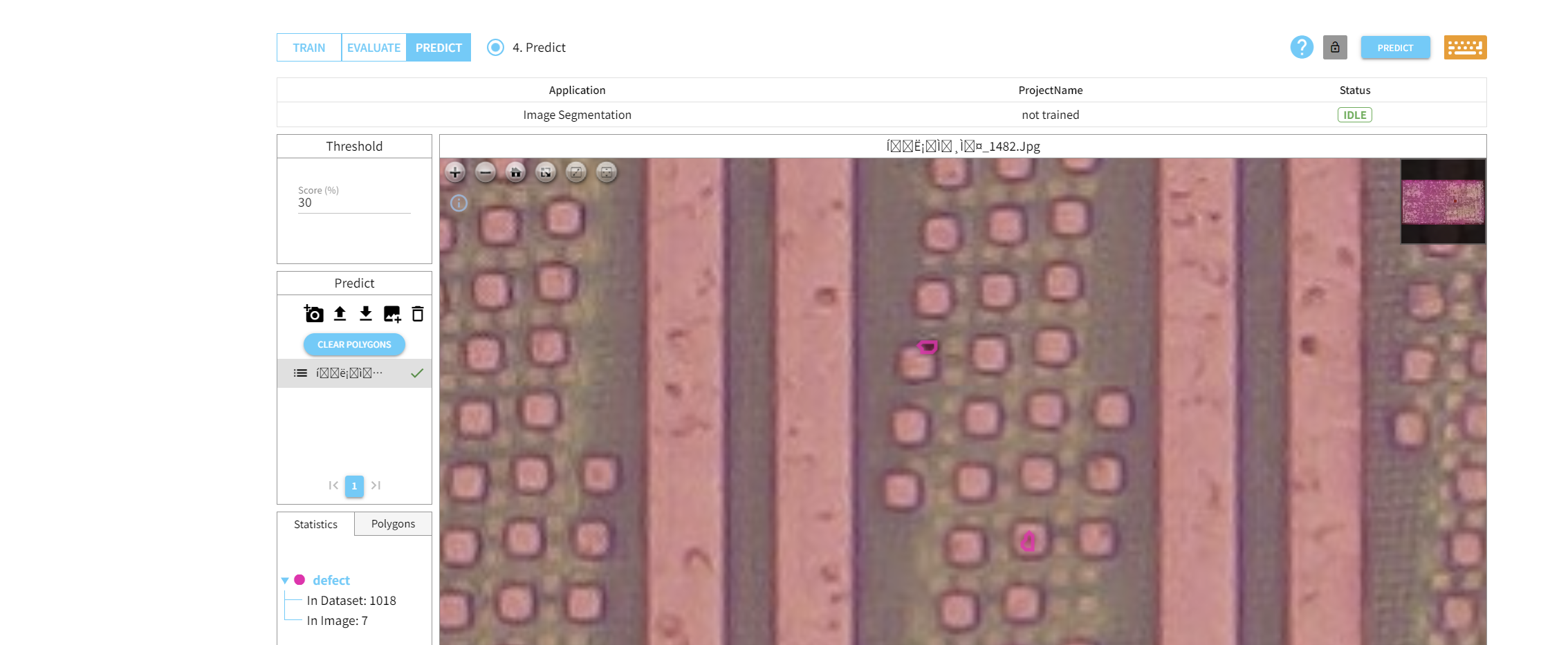

Model Inference

Once training is finished, move the micrograph file from TRAIN mode to PREDICT mode.

When we open PREDICT mode, we will notice that the file has been moved and the annotations have disappeared.

Now, let's check if the model trained with minimal annotations is functioning properly.

Set the threshold value to 30% and click the PREDICT button.

Set the division factor to 17 x 33, just like in TRAIN mode, and click the DIVIDE & PREDICT button.

The model will now perform defect inspection on the entire large-area micrograph.

While training was done using only labeled defects, the entire image must now be iterated for inspection, which takes a few minutes of GPU computing time on the free tier.

If you wish to complete inference more quickly or perform rapid inference on a production line, please contact us.

Once the inference is complete, all detected defects in the entire image will be displayed.

As shown in the right mini-map, a number of defects have been identified,

and as indicated in the lower left, the total number of detected defects exceeds 1,300.

Now, let's zoom in to verify the accuracy of the inference results.

As you can see, most defects similar to those labeled during training have been successfully identified.

In addition to these black defects, an optical micrograph can detect various types of defects.

Although this model is not perfect due to being trained with a small amount of annotation, its inference results can be reused to develop a more accurate model.

Deep Block is a no-code AI model development tool designed for large-area microscopy, suitable for use in on-premise settings, laboratories, and manufacturing processes.

This software toolbox enables rapid identification of even the tiniest defects and patterns within extensive ICs and wafers.

With this tool, you can develop your own inspection AI using just a microscope and micrograph, eliminating the need for costly equipment from major inspection companies like KLA and AMAT, thereby transforming your process and failure analysis.

Experience Deep Block for free and accelerate large-area microscopy effortlessly.