Revolutionizing Industries: Deposition Applications

Discover how deposition technology is revolutionizing industries with its applications in semiconductor manufacturing, electronics, MEMS, steelmaking, sputtering, and display manufacturing.

Understanding Deposition Technology

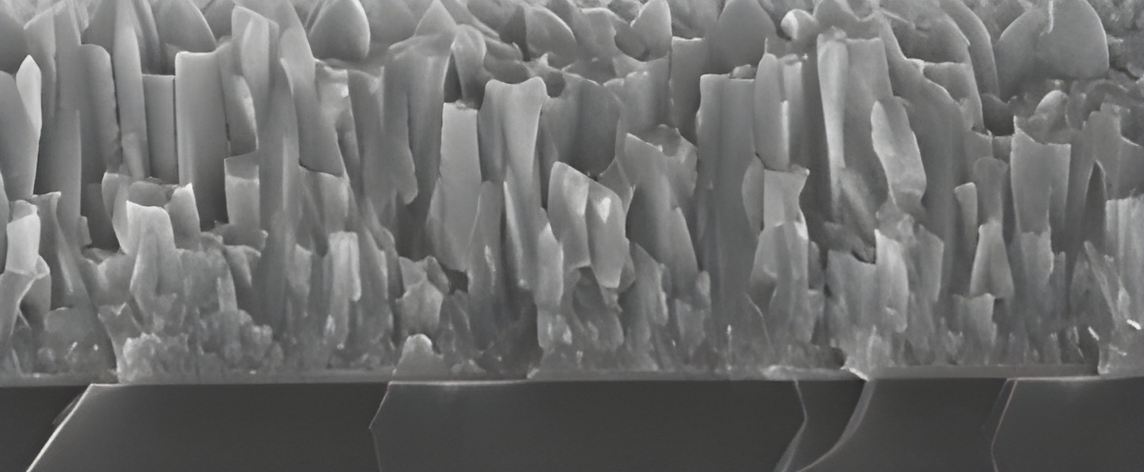

Deposition technology refers to the process of depositing thin layers of material onto a substrate. It involves the deposition of atoms or molecules onto a surface to create a new layer. This technology has found applications in various industries and has revolutionized the way we manufacture products.

One of the key aspects of understanding deposition technology is knowing the different deposition methods used. These methods include physical vapor deposition (PVD), chemical vapor deposition (CVD), and atomic layer deposition (ALD). Each method has its own advantages and is suitable for different applications.

Understanding the principles behind deposition technology is crucial for engineers and researchers working in industries that rely on this process. By understanding the underlying mechanisms, they can optimize the deposition process and improve the quality of the deposited films.

Semiconductor Manufacturing and Deposition

Semiconductor manufacturing heavily relies on deposition technology for the fabrication of integrated circuits and other electronic components. Deposition is used to create thin films of various materials that are essential for the functioning of semiconductors.

One of the key applications of deposition in semiconductor manufacturing is the creation of gate oxide layers. These layers are crucial for controlling the flow of current in a transistor. Deposition techniques such as CVD and ALD are used to create high-quality gate oxide layers with precise thickness and uniformity.

Deposition is also used in the creation of interconnect layers in semiconductors. These layers facilitate the connection between different components on a chip. By using deposition techniques, manufacturers can create multiple layers of interconnects with high precision and reliability.

Applications in Electronics

Deposition technology has numerous applications in the field of electronics. It is used in the manufacturing of various electronic components such as displays, sensors, and photovoltaic cells.

In display manufacturing, deposition is used to create thin films of organic or inorganic materials that emit light or control the flow of electrons. This technology is essential for the production of high-resolution displays with vibrant colors and fast response times.

Deposition is also used in the production of sensors, such as gas sensors and biosensors. By depositing sensitive materials onto a substrate, manufacturers can create sensors that can detect and measure specific substances or biological markers. This has applications in environmental monitoring, healthcare, and many other industries.

Furthermore, deposition plays a crucial role in the production of photovoltaic cells, which are used to convert sunlight into electricity. By depositing layers of different materials onto a substrate, manufacturers can create efficient solar cells that can harness solar energy and contribute to renewable energy generation.

Micro-Electromechanical Systems

Micro-electromechanical systems (MEMS) are devices that integrate mechanical elements, sensors, actuators, and electronics on a microscale. Deposition technology plays a crucial role in the fabrication of MEMS devices.

Deposition is used to create thin films of various materials that form the functional components of MEMS devices. These materials can include metals, semiconductors, polymers, and ceramics. By depositing these materials onto a substrate, manufacturers can create MEMS devices with precise dimensions and properties.

One of the key applications of deposition in MEMS is the creation of microsensors. Deposition techniques such as PVD and CVD are used to deposit sensitive materials onto a substrate, allowing the creation of sensors that can detect physical or chemical changes in the environment. These sensors have applications in fields such as automotive, aerospace, and healthcare.

Deposition is also used in the fabrication of microactuators, which are responsible for producing mechanical movements in MEMS devices. By depositing thin films of piezoelectric or shape memory materials, manufacturers can create actuators that can generate precise and controlled movements.

The use of deposition technology in MEMS has revolutionized the field of microscale devices and has paved the way for the development of innovative applications in various industries.

Steelmaking and Sputtering

Deposition technology has found applications in the steelmaking industry, particularly in the process known as sputtering. Sputtering is a technique used to deposit thin films of material onto a substrate by bombarding a target material with high-energy particles.

In steelmaking, sputtering is used to deposit protective coatings onto steel surfaces. These coatings provide corrosion resistance, wear resistance, and improved aesthetics to the steel products. By using deposition techniques, manufacturers can create steel products with enhanced performance and durability.

Deposition and Display Manufacturing

Deposition technology plays a crucial role in the manufacturing of displays, such as liquid crystal displays (LCDs) and organic light-emitting diode (OLED) displays.

In LCD manufacturing, deposition is used to create thin films of liquid crystal material between two glass substrates. These films control the alignment and orientation of liquid crystal molecules, allowing the display to produce images with high resolution and color accuracy.

Deposition is also used in the production of OLED displays. OLEDs consist of thin organic layers that emit light when an electric current is applied. Deposition techniques are used to create these organic layers, enabling the production of displays with high contrast, wide viewing angles, and energy efficiency.

The use of deposition technology in display manufacturing has revolutionized the visual experience, enabling the production of high-quality displays for various applications, including televisions, smartphones, and wearable devices.