Understanding Electron Diffraction in TEM

Learn the fundamentals of electron diffraction in Transmission Electron Microscopy (TEM) to explore material structures at the atomic level.

The Fundamentals of Electron Diffraction in TEM

Electron diffraction is a powerful technique used in Transmission Electron Microscopy (TEM) to analyze the crystalline structure of materials. When a beam of electrons is directed at a thin sample, the electrons interact with the atoms in the sample and are scattered, forming a diffraction pattern that can be captured and analyzed.

This diffraction pattern provides crucial information about the atomic arrangement and spacing within the material, enabling researchers to determine crystallographic orientations, identify phase structures, and even detect defects at the atomic level. Understanding these fundamentals is essential for applying electron diffraction effectively in various industries.

Abbe Theory

Lenses play a critical role in focusing the image of an object at a finite distance, making it easier to observe. The process of image formation via lens action is described by Abbe's imaging theory, which explains image formation in terms of wave optics.

Wave Optics and Image Formation

When light waves emanate from an object A, represented as f(x,y), they undergo Fraunhofer diffraction upon passing through the lens. At the rear focal plane of the lens, a diffraction pattern is formed, mathematically represented as the Fourier transform F(u,v) of f(x,y). In this transformation, the spatial coordinates (x,y), also known as real-space coordinates, are converted into reciprocal-space coordinates (u,v).

In the context of Transmission Electron Microscopy (TEM), the Fourier transform F(u,v) corresponds to the electron diffraction pattern formed at the rear focal plane of the objective lens. The diffracted waves at these points interfere with one another to reconstruct the original object A as an image A′ at the image plane.

The image-plane wave can be mathematically expressed as ψ(x,y), the inverse Fourier transform of F(u,v). This process involves two successive Fourier transforms, which effectively revert the diffraction pattern back into the spatial domain. The result is ψ(x,y), a transformed version of f(x,y), magnified, rotated, or otherwise modified by the optical system.

During this process, the object A is magnified into A′, with the magnification factor given by M=b/a, where b is the distance from the lens to the image plane, and a is the object-lens distance. If the optical system is free of aberrations, the resulting image A′ is referred to as the Gaussian image of A.

Imaging Modes in TEM: Contrast Techniques

In TEM, imaging is achieved by directing a highly parallel electron beam onto the sample. The transmitted and diffracted electron waves are focused by the objective lens, forming an intermediate image at the image plane. This image is then magnified and projected onto a fluorescent screen or a camera using the projection lens system.

Bright-Field (BF) and Dark-Field (DF) Imaging

At the rear focal plane of the objective lens, a diffraction pattern forms due to Bragg diffraction of electrons by the crystal lattice. To produce high-quality images, an objective aperture is used to selectively transmit specific parts of the diffraction pattern.

- Bright-Field (BF) Imaging:

- The aperture allows only the transmitted (central) beam to pass through.

- This produces a bright image since the majority of electrons pass through the sample without being diffracted.

- Dark-Field (DF) Imaging:

- The aperture selects a single diffracted beam, blocking the transmitted beam.

- The image highlights regions of the sample that satisfy the Bragg diffraction condition for the selected diffracted beam, resulting in a bright image against a dark background.

These imaging modes are typically optimized under the two-beam condition, where the transmitted beam and a single diffracted beam dominate. The resulting contrast arises due to amplitude differences in the transmitted and diffracted beams, referred to as amplitude contrast or diffraction contrast.

High-Resolution TEM (HRTEM) and Phase Contrast

In High-Resolution TEM (HRTEM), the diffraction pattern is aligned with the optical axis, and a larger objective aperture allows multiple beams to pass through simultaneously. These beams interfere to produce a detailed interference pattern on the image plane, enabling the visualization of atomic-scale features.

This mode relies on phase contrast, which arises due to differences in the phase of overlapping beams. As a result, HRTEM images reveal fine details about the crystal structure, such as atomic arrangements. Since phase contrast depends on the coherence and resolution of the TEM, achieving high-quality HRTEM images requires precise alignment and high-resolution instrumentation.

While both Conventional TEM (CTEM) and HRTEM modes are possible in a single instrument by varying the aperture size, CTEM is better suited for imaging defects like dislocations, stacking faults, grain boundaries, and precipitates, as it does not resolve atomic lattice structures.

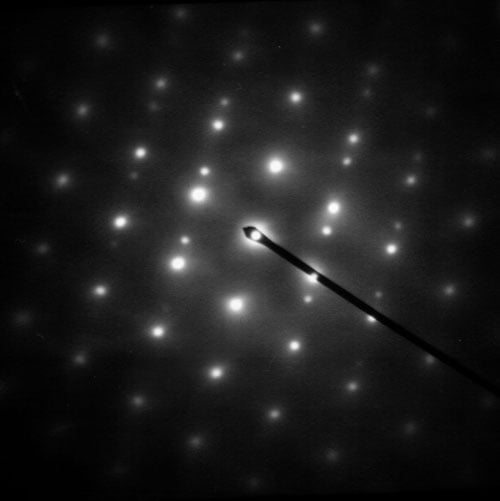

Diffraction Mode in TEM

In diffraction mode, a crystalline sample produces strong diffraction patterns due to Bragg's law, which describes the constructive interference of electrons diffracted by atomic planes. These patterns are formed at the rear focal plane of the objective lens and can be magnified and projected onto a fluorescent screen by the projection lens system.

- The focus of the diffraction pattern is adjusted by controlling the current in the diffraction lens.

- The magnification of the diffraction pattern depends on the current in the projection lens system. The diffraction pattern size is recorded at specific focal lengths, which are proportional to the sample-to-screen distance.

Selected-Area Electron Diffraction (SAED)

To obtain diffraction patterns from a localized region of the sample, a Selected-Area Electron Diffraction (SAED) aperture is used. Positioned at the image plane of the objective lens, this aperture restricts the field of view to a small region of the sample. The resulting SAED pattern corresponds to this limited area.

Convergent Beam Electron Diffraction (CBED)

For even smaller regions, the electron beam is focused to a diameter of approximately 50 nm using condenser lenses, producing a highly convergent beam. The resulting CBED patterns exhibit disc-shaped features instead of point patterns, as the electrons simultaneously interact with the sample at multiple angles. CBED provides rich information about crystal symmetry, strain, and lattice distortions.

Applications of Diffraction Patterns

Diffraction patterns in TEM reveal crucial information about the crystallinity and structure of the sample:

- Single Crystals:

- Produce sharp, well-defined spot patterns due to coherent diffraction.

- Polycrystalline Materials:

- Result in ring patterns, as diffraction spots from individual crystals are averaged due to their random orientations.

- Amorphous Materials:

- Show diffuse scattering or no distinct pattern, reflecting the lack of long-range order.

Diffraction patterns also enable the determination of lattice constants and crystal symmetry. For complex unit cells, additional atomic planes may cause destructive interference, reducing the intensity of specific diffraction spots. This phenomenon, known as the extinction effect, occurs when certain diffracted waves cancel each other out.

Mathematically, the extinction effect is related to the structure factor F(h,k,l), which depends on the atomic arrangement within the unit cell. When the condition hx+ky+lz=0 is met, the scattered intensities are significantly reduced, leaving only the contribution from individual atomic scattering.

Applications of Electron Diffraction in Semiconductor and Electronics Industries

Electron diffraction techniques, including SAED, are extensively used in the semiconductor and electronics industries for material characterization. They help in identifying crystal structures, verifying the quality of epitaxial layers, and detecting defects that could impact the performance of electronic devices.

In semiconductor manufacturing, electron diffraction is essential for developing and optimizing materials with specific electronic properties. It aids in the design of advanced gates like GAA, which are crucial for next-generation electronic devices.