Unveiling Silicon Wafer Manufacturing: Secrets & Innovations

Delve into the intricate process of silicon wafer manufacturing and uncover the secrets behind this essential component of modern technology.

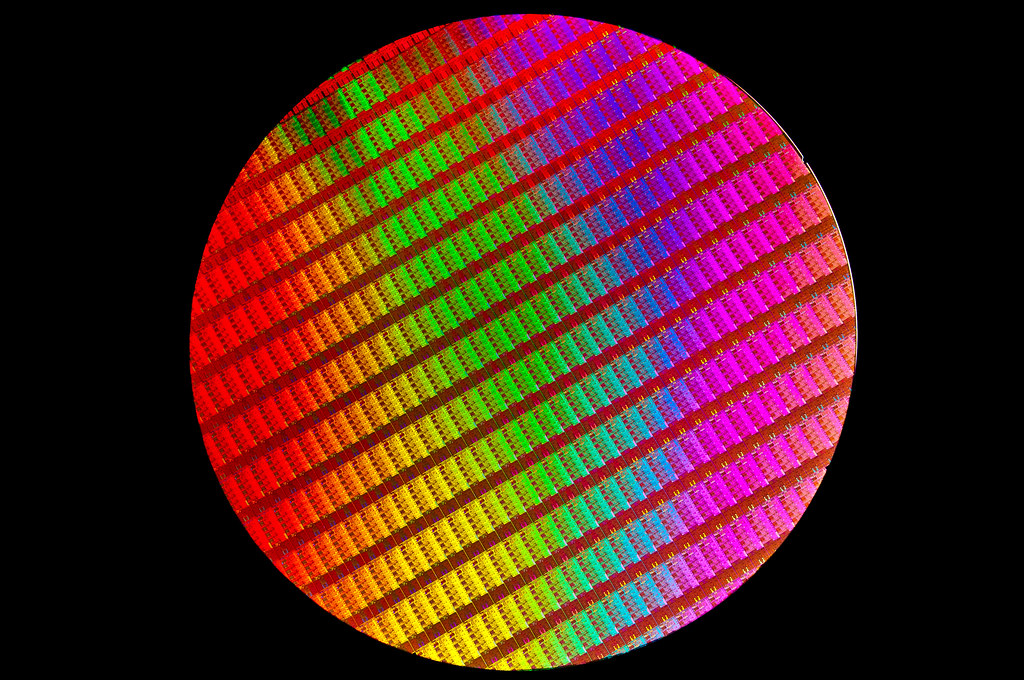

The Role of Silicon Wafers in Technology

Silicon wafers play a crucial role in technology, serving as the foundation for various electronic devices. These thin, circular discs are made from highly purified silicon and are used as the substrate for manufacturing integrated circuits, solar cells, and other semiconductor devices. Silicon wafers provide the necessary platform for the deposition, etching, and patterning of electronic components, making them an essential component in the production of modern technology.

Another important role of silicon wafers is their use in the fabrication of photovoltaic cells for solar panels. The unique properties of silicon, such as its ability to efficiently convert sunlight into electricity, make it an ideal material for solar energy generation. Silicon wafers are processed to create the necessary structures and layers required for capturing and harnessing solar energy, making them a key component in the renewable energy sector.

In addition to their use in electronic devices and solar panels, silicon wafers also find applications in other fields such as MEMS (Microelectromechanical Systems) technology, where they serve as the substrate for microsensors and microactuators. The versatility of silicon wafers makes them indispensable in various technological advancements, contributing to the advancement of industries and the improvement of everyday life.

From Sand to Silicon: The Manufacturing Process

The manufacturing process of silicon wafers begins with the extraction of silicon from sand, one of the most abundant materials on Earth. The sand is purified and processed to obtain high-purity silicon, which serves as the raw material for wafer production. The purification process involves several steps, including crushing, washing, and chemical treatments to remove impurities and contaminants.

Once the silicon is purified, it undergoes a series of chemical and physical processes to transform it into a usable form for wafer manufacturing. The silicon is melted and then solidified into ingots, which are cylindrical blocks of pure silicon. These ingots are then sliced into thin wafers using a process called wafering. The wafers are carefully polished to achieve a smooth and flat surface, ensuring uniformity and quality.

After wafering and polishing, the wafers undergo further processing steps to create the desired features and structures. This includes processes such as doping, where specific impurities are intentionally added to modify the electrical properties of the silicon, and deposition, where thin layers of materials are deposited onto the wafer surface using techniques such as chemical vapor deposition or physical vapor deposition.

The manufacturing process also includes steps for testing and quality control to ensure that the produced wafers meet the required specifications. This involves inspecting the wafers for defects, measuring their electrical properties, and performing various tests to ensure their reliability and performance.

Overall, the manufacturing process of silicon wafers is a complex and precise operation that involves multiple stages and techniques. Each step plays a crucial role in producing high-quality wafers that meet the demands of modern technology.

Crucial Steps in Silicon Wafer Production

Silicon wafer production involves several crucial steps that are integral to the manufacturing process. These steps ensure the creation of high-quality wafers that meet the stringent requirements of the semiconductor industry.

One of the key steps in silicon wafer production is the purification of silicon. This process involves removing impurities and contaminants from the raw material, typically sourced from sand. Purification techniques such as crushing, washing, and chemical treatments are employed to achieve high-purity silicon, which forms the basis for wafer manufacturing.

Another crucial step is the slicing of silicon ingots into thin wafers. This process, known as wafering, requires precision cutting techniques to achieve the desired thickness and flatness. The wafers are then polished to further enhance their surface quality and ensure uniformity.

Quality control measures are implemented throughout the production process to ensure the reliability and performance of the produced wafers. These measures include inspection for defects, electrical testing to evaluate the wafers' properties, and various reliability tests to assess their long-term performance.

By carefully executing these crucial steps, manufacturers can produce high-quality silicon wafers that are essential for the advancement of technology and various industries.

Quality Control Measures in Silicon Wafer Manufacturing

Quality control is a critical aspect of silicon wafer manufacturing to ensure the production of wafers that meet the highest standards of reliability and performance. Various measures are implemented throughout the manufacturing process to identify and eliminate defects, maintain consistency, and ensure the overall quality of the produced wafers.

One of the primary quality control measures is the inspection of wafers for defects. Optical inspection techniques, such as microscopy and automated inspection, are used to detect and categorize defects on the wafer surface. Defects can include particles, scratches, contamination, or other imperfections that can affect the functionality and reliability of the wafers.

By implementing stringent quality control measures, manufacturers can produce silicon wafers that meet the highest standards of reliability, performance, and consistency. These measures are crucial for ensuring the functionality and longevity of electronic devices and other semiconductor-based technologies.

Innovations and Future Trends in Silicon Wafer Technology

Silicon wafer technology has been continuously evolving, driven by the demands of the semiconductor industry and the need for more advanced and efficient electronic devices. Several innovations and future trends are shaping the development of silicon wafer technology, paving the way for new possibilities and applications.

One of the key innovations in silicon wafer technology is the transition to larger wafer sizes. Larger wafer sizes, such as 300mm and beyond, offer several advantages, including increased productivity, higher device yield, and cost reduction. The larger surface area of these wafers allows for the integration of more devices, leading to higher performance and functionality.

Another significant trend is the development of novel materials for wafer manufacturing. While silicon remains the dominant material, there is growing interest in alternative materials such as gallium nitride (GaN) and silicon carbide (SiC). These materials offer unique properties that make them suitable for specific applications, such as power electronics and high-frequency devices. The integration of these materials with silicon wafers opens up new possibilities for advanced device design and performance.

Advancements in wafer processing techniques are also driving innovation in silicon wafer technology. Techniques such as epitaxy, which involves the deposition of crystalline layers on the wafer surface, enable the creation of complex structures and heterostructures with enhanced properties.

The integration of wafer-level packaging (WLP) is another emerging trend in silicon wafer technology. WLP involves the integration of packaging and interconnects directly at the wafer level, eliminating the need for traditional packaging processes. This approach offers several benefits, including reduced form factor, improved electrical performance, and enhanced thermal management. WLP enables the development of more compact and efficient electronic devices, particularly in the field of microelectronics and IoT (Internet of Things).

Furthermore, the development of advanced metrology and inspection techniques is crucial for ensuring the quality and reliability of silicon wafers. Techniques such as atomic force microscopy (AFM), scanning electron microscopy (SEM), and X-ray diffraction (XRD) provide detailed characterization and analysis of wafer properties, defects, and structures. These techniques aid in process optimization, defect detection, and quality control, enabling manufacturers to produce wafers with improved performance and reliability.

In conclusion, silicon wafer technology continues to evolve and innovate, driven by advancements in materials, processing techniques, and characterization methods. These innovations and future trends hold great potential for enhancing the performance, functionality, and reliability of electronic devices and shaping the future of technology.